In the Experimental Archaeology seminar, which was held by Ms. Marie Usadel M.A., the students were able to submit various proposals for their own experiments and carry them out after extensive research and preparation. The days on which the experiments were carried out were 28.01.2023 and 21.02.2023.

One of the processes to be used was the Wax Casting, which is used in metallurgy.

In the process, wax is first heated slightly so that it is malleable. Normal candle wax and packaging wax for the food industry were used for this experiment. After warming the wax, the students were able to shape it to their liking: some formed necklace pendants, others were inspired by our teaching excavation projects and tried working on complex shapes such as the well-known bronzetti of Iron Age Sardinia.

Once the figure was fully formed, the students encased the wax mold in clay. Care had to be taken to ensure that there was enough air supply, otherwise the mold could simply burst.

After drying, the molds were slightly heated in the institute's drying cabinet so that the wax could be melted and poured out - thus creating a negative mold of the original wax figure.

Bronze was used for the casting, which was melted in a melting pot in the institute's furnace.

The clay mold was previously placed in a container filled with sand. This is practical because sand is not flammable. Bronze that is poured next to it would simply cool down there and can be reused. Secondly, the clay mould can be stabilized in this way and there is less risk of it slipping or falling over.

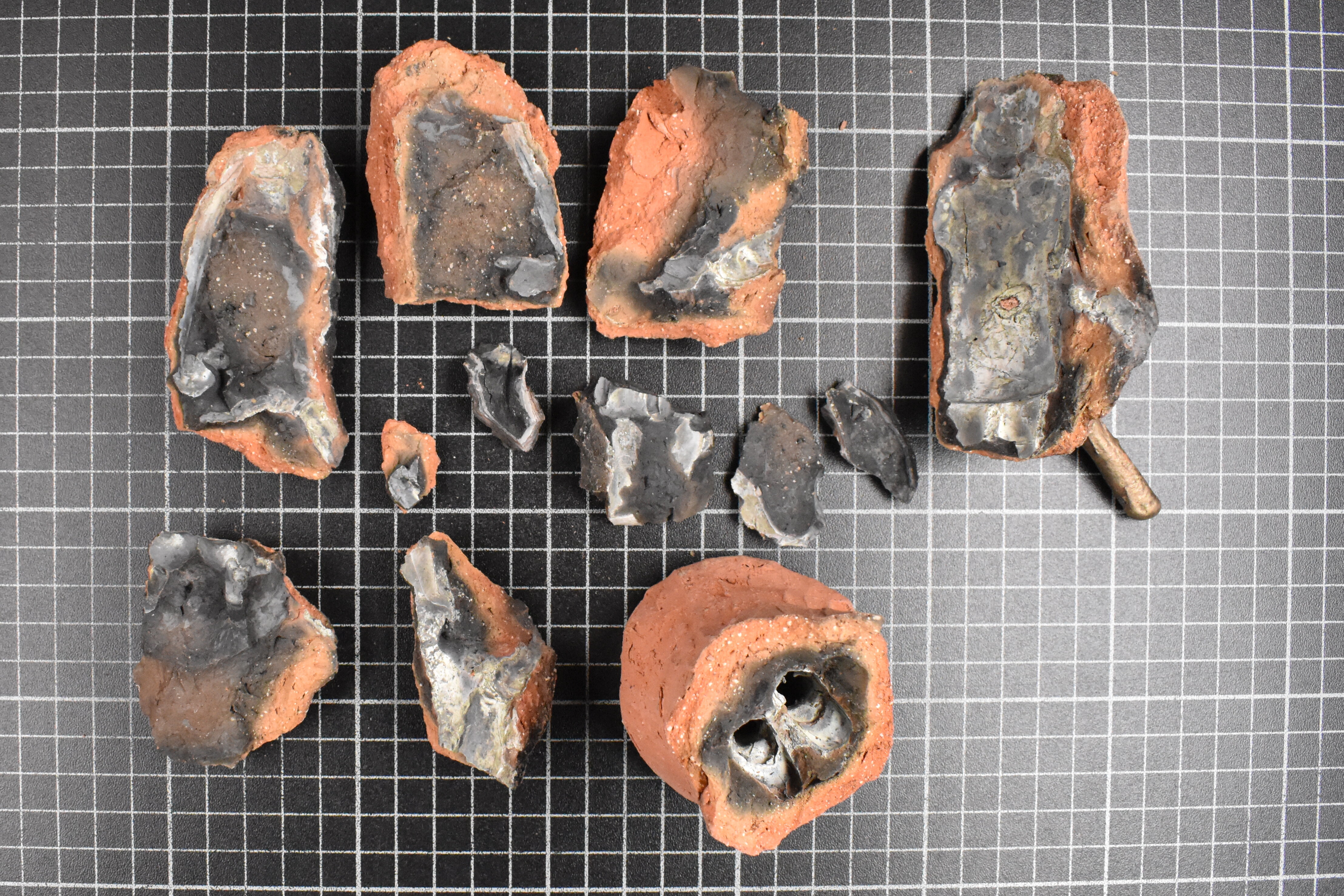

The molds cooled down relatively quickly. The metal hardened completely within a few minutes. Once the molds had cooled completely, they were taken outside. There, the outer layer of clay was carefully broken up with a hammer and chisel and chipped off.

After the clay was broken off, the finished pieces came to light. It was noticeable that even the smallest details carved into the wax were visible in the finished metal object. Both figurative objects and pendants were made and remained intact.

After the objects had rested for a while, they were polished and could then be exhibited.